Some inventions fade into obscurity, while others stand the test of time, remaining as relevant and essential today as they were when first conceived. The micrometer falls into the latter category. Despite being invented centuries ago, this incredibly precise measuring instrument continues to play a crucial role in engineering, machining, and manufacturing worldwide.

But what makes the micrometer so special? Why has it remained unchallenged as the go-to tool for high-precision measurements? Let’s dive into the history, mechanics, and importance of this simple yet brilliant invention.

The History of the Micrometer: A Tool That Defined Accuracy

The origins of the micrometer date back to the 17th century, when William Gascoigne first developed a screw-based measuring device. However, the micrometer as we know it today owes much of its evolution to Jean Laurent Palmer, a French inventor who refined the tool in 1848.

Palmer’s design, known as the screw micrometer gauge, became the foundation for modern micrometers. Over time, engineers and manufacturers adopted it for its unmatched accuracy and ease of use, making it a staple in workshops and laboratories across industries.

By the late 19th century, manufacturers such as Brown & Sharpe in the United States began mass-producing micrometers, further cementing their status as an indispensable tool in precision engineering.

How Does a Micrometer Work? The Science Behind the Precision

At first glance, the micrometer may seem like a simple measuring instrument, but its precision mechanics make it one of the most reliable tools ever created.

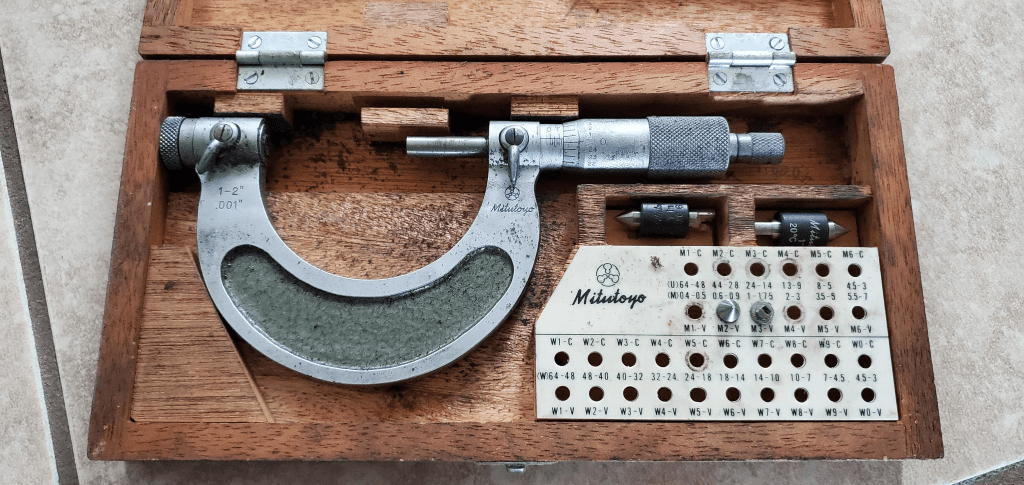

A standard micrometer consists of:

- Frame – Provides a stable structure to ensure measurement accuracy.

- Anvil – A stationary surface against which the object is measured.

- Spindle – A movable screw that makes contact with the object being measured.

- Thimble & Ratchet Stop – Controls the spindle movement to ensure a consistent, precise measurement.

- Sleeve (or Barrel) with a Scale – Displays the measurement reading in micrometers or inches.

When the spindle moves toward the anvil, it measures objects down to the smallest fraction of a millimeter or inch. Thanks to the fine-threaded screw mechanism, even the tiniest variations in size can be detected, ensuring extreme accuracy.

Types of Micrometers: Choosing the Right One for the Job

Not all micrometers are the same—different industries require specialized micrometers for various applications. Here are the most common types used today:

1. Outside Micrometer (External Micrometer)

- Used for measuring external dimensions of objects, such as thickness or diameter.

- Commonly used in machining, metalworking, and quality control.

2. Inside Micrometer

- Measures internal dimensions, such as the diameter of holes or bores.

- Essential in mechanical and automotive engineering.

3. Depth Micrometer

- Measures depth of slots, holes, and recesses.

- Often used in manufacturing and tool-making.

4. Digital Micrometer

- Offers digital readouts for increased precision and ease of use.

- Used in industries where absolute accuracy is required, such as aerospace and medical device manufacturing.

5. Thread Micrometer

- Specifically designed to measure the pitch diameter of screw threads.

- Crucial in bolt and fastener manufacturing.

Why the Micrometer Remains Essential in Modern Industries

Despite the rise of digital measurement tools and laser-based metrology, the micrometer has not been replaced. Why? Because it offers unmatched precision, durability, and reliability. Here’s why industries still depend on it:

✔️ Extreme Precision – Micrometers provide measurements accurate to within 0.001 mm (or even finer), making them indispensable in fields where tolerances are razor-thin.

✔️ Durability and Longevity – Unlike many electronic measuring tools, micrometers are built to last with rugged metal frames and precise mechanical components.

✔️ No Need for Power or Batteries – Traditional micrometers work without electricity, making them reliable in fieldwork and industrial environments where power sources may be limited.

✔️ Ease of Use – Once mastered, a micrometer allows for quick and repeatable measurements, reducing errors and improving workflow efficiency.

Industries That Depend on Micrometers

The micrometer is not just for machinists and engineers—it plays a critical role across multiple industries.

🔹 Manufacturing & Machining – Used for quality control in automobile, aerospace, and heavy machinery production.

🔹 Scientific Research & Laboratories – Essential for microscopy, materials science, and nanotechnology.

🔹 Aerospace Engineering – Ensures exact tolerances in aircraft component manufacturing.

🔹 Medical Device Manufacturing – Used in producing surgical instruments, implants, and precision tools.

🔹 Watchmaking & Jewelry – Helps create exquisite timepieces and delicate ornaments with high precision.

How to Use a Micrometer Like a Pro

While a micrometer is incredibly precise, it requires proper handling to ensure accurate results. Follow these steps for perfect micrometer measurements every time:

1️⃣ Ensure Calibration – Always check if your micrometer is properly calibrated before use. A misaligned micrometer can lead to measurement errors.

2️⃣ Clean the Object & Micrometer – Even small dust particles can affect accuracy, so clean both the measuring faces and the object being measured.

3️⃣ Position the Object Correctly – Make sure the object is aligned perfectly between the anvil and spindle before taking a reading.

4️⃣ Use the Ratchet Stop – Instead of applying manual pressure, use the ratchet mechanism to avoid over-tightening and distorting measurements.

5️⃣ Read the Scale Carefully – If using a traditional vernier micrometer, take your time to read the sleeve, thimble, and vernier scales correctly. For digital micrometers, simply note the displayed reading.

6️⃣ Record and Verify Measurements – Always double-check measurements for consistency before finalizing data.

Final Thoughts: The Micrometer’s Lasting Impact

The micrometer is a testament to the brilliance of simple yet highly effective design. Despite being invented centuries ago, it remains a cornerstone of precision measurement in modern industries.

From engineering workshops to cutting-edge scientific research, the micrometer continues to be one of the most trusted tools for ensuring accuracy. Whether it’s measuring the smallest components in an aircraft engine or crafting the intricate gears of a luxury watch, the micrometer proves that some inventions never go out of style.

So, the next time you see a mechanic, machinist, or scientist carefully using a micrometer, remember—you’re witnessing a timeless piece of innovation at work. 🛠️