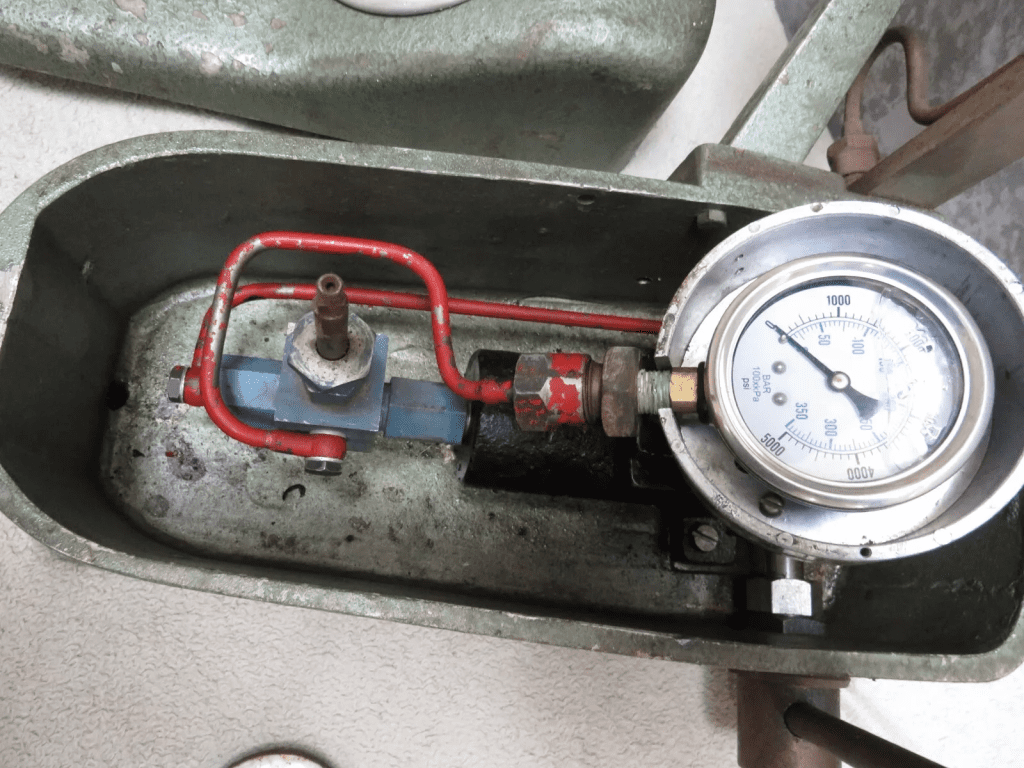

The vintage hydraulic gauge pump brake bleeder parts washer is a fascinating artifact in the world of automotive maintenance. This tool, designed for both brake bleeding and cleaning parts, represents a significant step in the evolution of car repair technology. Not only does it simplify complex tasks, but it also serves as a testament to the innovative solutions that mechanics developed in response to growing automotive complexities.

The Rise of Hydraulic Brake Systems

Hydraulic brake systems revolutionized the automotive industry in the early 20th century. As vehicles became more advanced and faster, the need for reliable braking systems grew exponentially. Before hydraulic systems, cars relied on mechanical brakes, which were prone to inefficiencies and failures. Hydraulic brakes, however, offered more consistent performance, using fluid pressure to apply braking force evenly across the system.

With the rise of hydraulic braking systems came the need for specialized tools to maintain them. One of the key challenges was brake bleeding—the process of removing air bubbles from the brake lines to ensure optimal performance. Air in the brake lines can cause spongy brakes and, in extreme cases, brake failure. This is where the hydraulic gauge pump brake bleeder entered the picture, a groundbreaking tool that allowed mechanics to easily monitor and manage hydraulic pressure during brake bleeding.

The Innovation Behind the Hydraulic Gauge Pump Brake Bleeder

The hydraulic gauge pump brake bleeder was more than just a simple tool; it was a game-changer. Its key innovation lay in its design: a gauge that allowed mechanics to monitor the pressure within the brake system as they pumped the handle to create hydraulic force. This gave technicians the precision needed to ensure that air was fully expelled from the brake lines, resulting in a firm, responsive brake pedal.

This tool became indispensable for automotive repair shops and DIY mechanics alike. Its ease of use—attach, pump, and monitor—made brake bleeding more efficient and reduced the likelihood of error. Before the advent of this tool, brake bleeding was a tedious process that often required multiple mechanics to get right. The hydraulic gauge pump bleeder simplified the job and made it something a single mechanic could manage quickly and accurately.

Dual Purpose: Parts Washer Functionality

Another standout feature of this vintage tool was its parts washer capability. Brake components are constantly exposed to dust, grime, and brake fluid, which can affect their performance and lifespan. Cleaning brake parts was (and still is) essential to maintaining the overall health of the braking system. The hydraulic gauge pump brake bleeder parts washer allowed mechanics to clean these components effectively, ensuring longevity and optimal function.

This dual-purpose design was a stroke of genius. Mechanics could use the tool to bleed brakes and then clean the brake parts with the same device, streamlining the entire maintenance process. It saved time, reduced the need for multiple tools, and ensured that vehicles left the workshop with fully functional, clean brake systems.

How the Tool Was Used in the Workshop

The operation of the vintage hydraulic gauge pump brake bleeder was straightforward yet effective. First, the tool was connected to the vehicle’s brake system. The mechanic would then pump the handle to build hydraulic pressure, observing the gauge closely to ensure optimal pressure was achieved. The gauge provided critical feedback, indicating whether air bubbles remained in the system or if the bleeding process had been successful.

By keeping a close eye on the pressure readings, the mechanic could confidently complete the brake bleeding process, ensuring the vehicle’s brakes were safe and responsive. This efficiency made the tool popular not only in professional repair shops but also among DIY enthusiasts who wanted to maintain their vehicles at home.

The Legacy of the Vintage Hydraulic Gauge Pump Brake Bleeder

Though modern automotive repair technology has advanced significantly, the core principles introduced by the hydraulic gauge pump brake bleeder remain relevant. Today, electronic brake bleeding systems can automate much of the process, but the fundamental concept—using pressure to remove air from hydraulic systems—stems directly from the innovations of these vintage tools.

In many ways, the vintage hydraulic gauge pump brake bleeder is seen as a bridge between old-school, manual methods and the high-tech solutions we rely on today. It provided a level of precision and ease that was previously unattainable, and its influence can still be felt in modern tools.

Why Collectors and Enthusiasts Still Love This Tool

The vintage hydraulic gauge pump brake bleeder has gained a cult following among car enthusiasts and collectors. It represents not just a functional tool but a piece of history that speaks to the ingenuity of past generations of mechanics. Vintage car shows, restoration projects, and collector forums are filled with admiration for this simple yet powerful device.

Collectors often seek out these tools, valuing both their historical significance and their practical functionality. In some cases, these tools are still in use today, passed down from one mechanic to another, standing the test of time in an industry that’s always evolving.

Conclusion: A Symbol of Progress in Automotive Maintenance

The vintage hydraulic gauge pump brake bleeder parts washer is more than just an old tool—it’s a symbol of the progress that has shaped the automotive repair industry. From its role in simplifying brake bleeding to its dual-purpose design as a parts washer, this tool showcases the ingenuity and practicality of past technologies.

While today’s mechanics may have more advanced options at their disposal, the core ideas behind tools like this one remain foundational. The legacy of the hydraulic gauge pump brake bleeder reminds us of the importance of innovation, precision, and care in automotive maintenance. As we look to the future of the industry, we also honor the contributions of these vintage tools that helped pave the way for modern vehicle safety and performance.