The Micrometer: A Precision Tool Through the Ages

In the realm of precision measurement, the micrometer stands out as one of the most impactful tools ever created. Initially devised to tackle the challenges of accurately measuring small dimensions, the micrometer has evolved into a hallmark of engineering precision. Let’s delve into its fascinating history, usage, and lasting influence in modern manufacturing and engineering.

The Micrometer’s Revolutionary Inception

Dating back to the early 19th century, the micrometer screw gauge was the brainchild of French inventor Jean Laurent Rixens, who patented it in 1829. At the time, engineers and machinists were grappling with the limitations of existing measurement tools when tackling small dimensions. Rixens’ invention provided a groundbreaking solution, enabling unprecedented precision.

Initially embraced by mechanical engineering and manufacturing industries, the micrometer allowed for the exact measurement of parts, crucial for maintaining quality and functionality. Over time, its design has seen continuous refinements, enhancing both its accuracy and user-friendliness. Early models incorporated vernier scales and high-quality materials, boosting durability and precision.

Evolution and Widespread Adoption

As the Industrial Revolution progressed through the 19th and early 20th centuries, the demand for precise tools surged. The micrometer’s design evolved to meet the needs of various industries, from automotive to aerospace. This evolution enabled measurement in incredibly small increments—often down to millionths of a meter—making the micrometer indispensable.

The introduction of the vernier scale was a key improvement, allowing users to make even more accurate readings. Manufacturers designed micrometers for specific tasks, such as measuring internal dimensions, external diameters, and depths, adapting to the specialized needs of different industries.

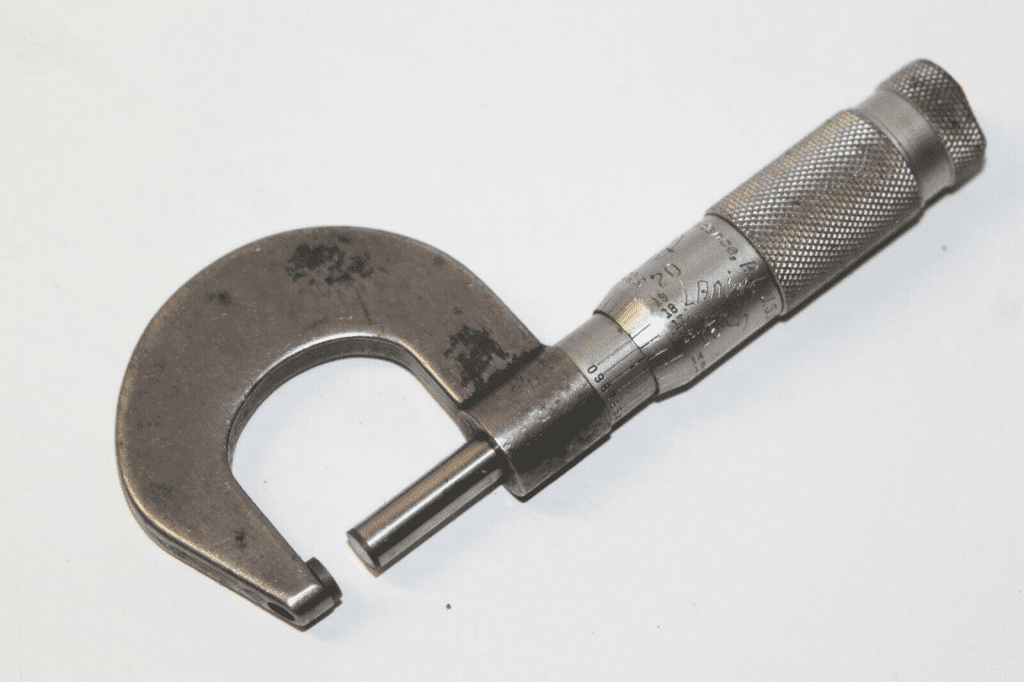

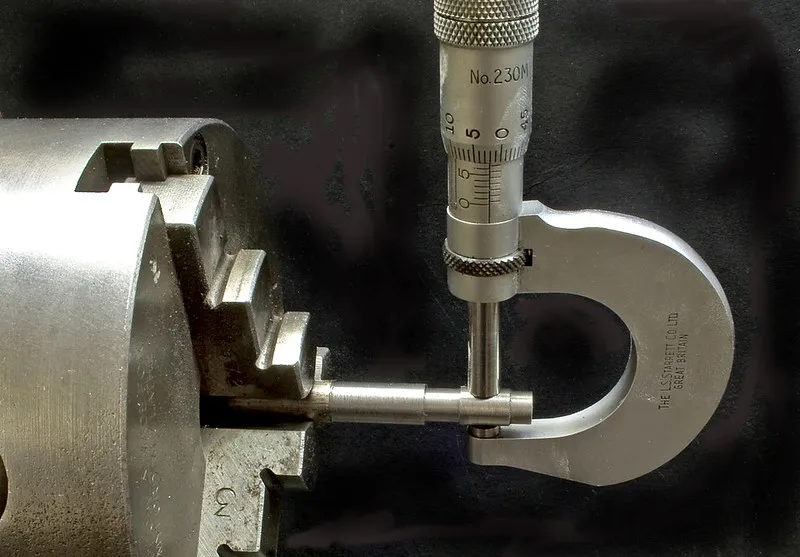

How the Vintage Micrometer Works

The vintage micrometer operates using a straightforward yet highly effective screw mechanism. Key components include a calibrated screw, a spindle, and an anvil. The object to be measured is placed between the anvil and spindle. Turning the screw moves the spindle, which compresses the object gently for measurement.

This mechanism allows for incredible precision, with each screw turn correlating to a specific increment on the scale. This design enables the accurate measurement of material thickness, diameters, and distances between surfaces, making the micrometer an essential tool for industries where precision is paramount.

Precision Across Multiple Industries

Throughout its history, the micrometer has been utilized across various industries. In automotive and aerospace sectors, precise measurements are vital for quality control and functionality. Micrometers are crucial in ensuring components meet exact tolerances and prevent failures.

In precision engineering, micrometers have been instrumental in manufacturing delicate mechanisms and cutting-edge electronics. They have enabled the creation of smaller, more intricate parts, driving technological advancements.

The Enduring Legacy of the Vintage Micrometer

Even before the digital era introduced electronic measuring devices, the vintage micrometer was a cornerstone of quality control. Its legacy lies not only in functionality but also in representing precision engineering and craftsmanship.

Despite modern advancements, vintage micrometers are still prized by collectors and enthusiasts for their historical significance and tactile feedback. They remain symbols of precision and reliability.

From Analog to Digital

While vintage micrometers hold historical value, modern iterations have embraced digital technology, offering advantages such as easy-to-read displays and quick metric-imperial conversions. Electronic micrometers can store data and integrate with software, streamlining workflows and enhancing efficiency.

However, the core principle of precision measurement remains unchanged, reaffirming the micrometer’s vital role in ensuring quality standards in engineering and manufacturing.

Conclusion

Since Jean Laurent Rixens’ original 1829 design, the micrometer has evolved and remained crucial in industries demanding accuracy. It symbolizes precision engineering and human ingenuity, showcasing our timeless pursuit of perfection. Whether in museums or workshops, the micrometer’s legacy endures, testament to the innovation that has driven technological progress for nearly two centuries.