At first glance, it might look like a piece of scrap metal, something forgotten in an old toolbox or tucked away in a dusty workshop. But don’t let its worn-out appearance fool you—this vintage tool has helped shape industries, build machines, and ensure precise craftsmanship for centuries.

The answer? A pair of calipers.

This once-essential measuring tool, despite its age and rust, still holds the power to tell an exact story. Used for measuring dimensions with remarkable accuracy, calipers have been a go-to device for engineers, machinists, and craftsmen long before digital tools took over.

What Are Calipers? A Timeless Measuring Tool

Calipers are precision instruments designed to measure thickness, outer diameter, inner diameter, length, width, and depth of an object. They have been widely used in various industries, from metalworking and carpentry to watchmaking and mechanical engineering.

Unlike a simple ruler or measuring tape, calipers allow users to take highly precise measurements, sometimes down to fractions of a millimeter. This level of accuracy is crucial in fields where even the slightest miscalculation can lead to errors in construction, design, or assembly.

A Brief History of Calipers: Measuring Through the Ages

The concept of calipers dates back thousands of years. Some of the earliest versions were found in ancient Greek and Roman civilizations, where they were used to measure distances and dimensions in architecture and sculpture.

Over time, the design of calipers evolved. By the 17th and 18th centuries, metal calipers became standard tools in workshops, helping artisans and craftsmen create precision-engineered parts.

Before the invention of digital measuring tools, calipers were one of the most reliable and efficient ways to ensure accuracy. Even today, vintage calipers are still valued for their durability and precision.

Different Types of Calipers and Their Uses

Not all calipers are the same. Over time, various types have been developed to suit different applications. Here are the most common ones:

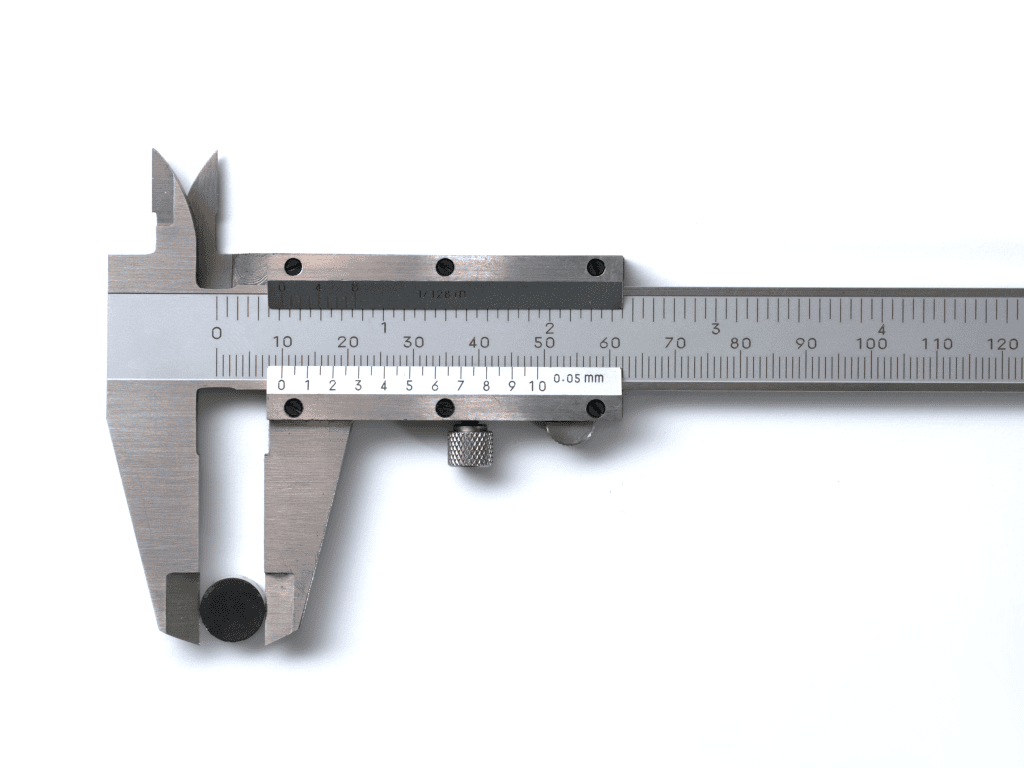

1. Vernier Calipers

One of the most classic and widely used types, Vernier calipers have a primary scale and a sliding secondary scale (called the Vernier scale) that allows for extremely accurate measurements. These were the go-to tools for engineers and machinists before digital calipers became mainstream.

2. Dial Calipers

A step up from Vernier calipers, dial calipers feature a rotating dial display that makes it easier to read measurements. They eliminate the need for manually interpreting small marks on a scale, making them more user-friendly.

3. Digital Calipers

The modern version of calipers, digital calipers display measurements on an electronic screen, offering instant readings in different units (millimeters, inches, etc.). They are widely used in manufacturing and precision engineering today.

4. Inside and Outside Calipers

Before Vernier and digital calipers took over, traditional inside and outside calipers were used to measure diameters and widths. These old-school calipers relied on the user manually adjusting the tool to fit around or inside an object, then comparing it against a ruler.

Why Calipers Remain a Valuable Tool

Even in an age where digital tools and laser measurement devices dominate, calipers remain a trusted tool for many professionals. Here’s why:

- Unmatched Accuracy: Even the simplest Vernier calipers can measure down to 0.02 mm, providing a level of precision that is hard to match.

- Durability: Unlike electronic devices that rely on batteries and sensors, traditional calipers are built to last, often made of hardened steel or brass.

- Versatility: Whether you need to measure the thickness of a sheet, the diameter of a pipe, or the depth of a hole, calipers can handle a wide range of tasks.

- Independence from Technology: Unlike digital tools that can malfunction or require calibration, manual calipers never fail—they work as long as they’re well-maintained.

How to Use a Pair of Calipers Like a Pro

For those unfamiliar with using calipers, here’s a quick guide to getting precise measurements:

- Adjust the jaws of the calipers to fit around or inside the object you’re measuring.

- Read the measurement from the scale (for manual calipers) or the digital display (for digital calipers).

- Ensure proper alignment to avoid measurement errors.

- Use the fine adjustment screw (if available) for even more precision.

- Record your measurement and reset the calipers for the next use.

With proper handling, even an old, rusty caliper can still deliver precise and accurate readings.

Restoring Vintage Calipers: Bringing the Past Back to Life

If you happen to find a rusted pair of calipers in an antique store, a family toolbox, or a flea market, don’t dismiss them just yet! Restoring vintage calipers is easier than you think.

Here’s how you can bring an old pair of calipers back to life:

- Remove rust using white vinegar or a rust remover solution. Soaking the tool overnight can loosen built-up corrosion.

- Scrub with steel wool or a wire brush to remove any remaining rust or dirt.

- Lubricate with oil to prevent future corrosion and ensure smooth operation.

- Polish the scale markings for better readability, especially on older models.

With a little effort, a neglected pair of calipers can regain its former glory, making it functional again while preserving its historical value.

The Timeless Legacy of Calipers

From ancient civilizations to modern engineering, calipers have played a crucial role in precise measurement. They may not have the flashiness of high-tech measuring tools, but their reliability, durability, and accuracy have stood the test of time.

Even in today’s digital world, many professionals still trust traditional calipers for critical tasks. And for collectors and vintage tool enthusiasts, an old, well-worn pair of calipers tells a story of craftsmanship, precision, and innovation.

So, next time you come across an old, rusty caliper, take a closer look. It’s not just a tool—it’s a piece of history.