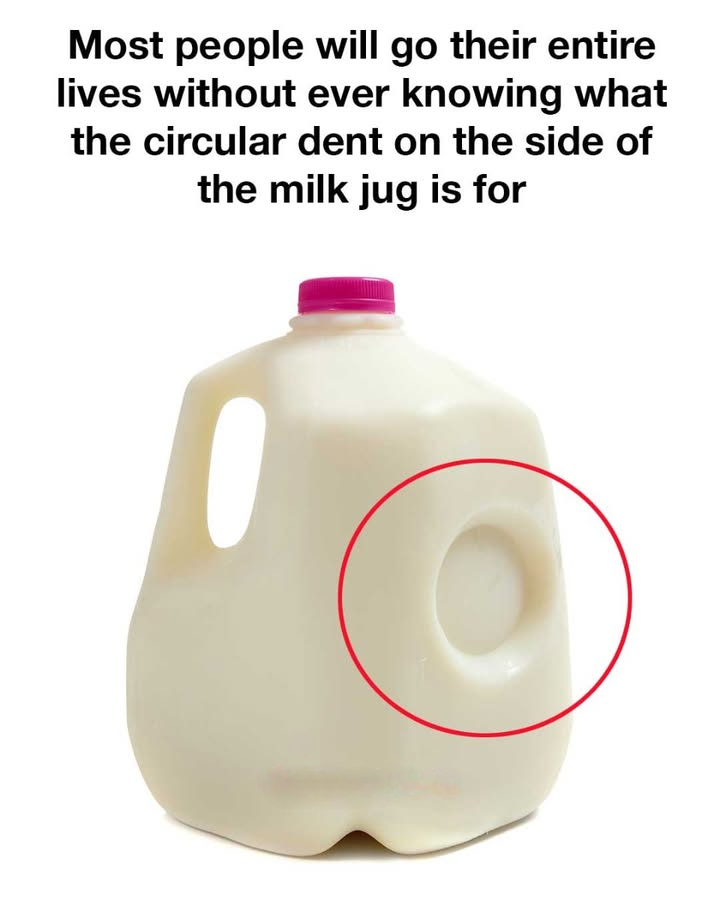

Understanding the Hidden Purpose of the Milk Jug Dent

Ever noticed that circular dent on the side of your plastic milk jug? You probably have—but like most of us, you might have shrugged it off as a random design or just part of the molding process. Surprise! That little indentation is anything but random. It’s one of the smartest, most functional features in modern food packaging—and it deserves some serious recognition.

Let’s dig into why this overlooked detail actually plays a huge role in the safety, efficiency, and sustainability of how your milk gets from the dairy to your fridge.

The Functionality Behind the Dent: More Than Meets the Eye

First off, this dent isn’t a flaw—it’s a feature. Engineers designed it to make milk jugs safer and more adaptable. Think of it as the jug’s pressure valve. When milk expands due to temperature changes—say during transport or storage—the dent allows the jug to flex without cracking. It contracts or expands slightly, absorbing that pressure.

It’s kind of like how bubble wrap protects fragile packages. This tiny design element protects your gallon of milk from splitting open just because it sat in a warm truck for too long. Cool, right?

Video: Why Milk Jugs Have These Dimples 🤨

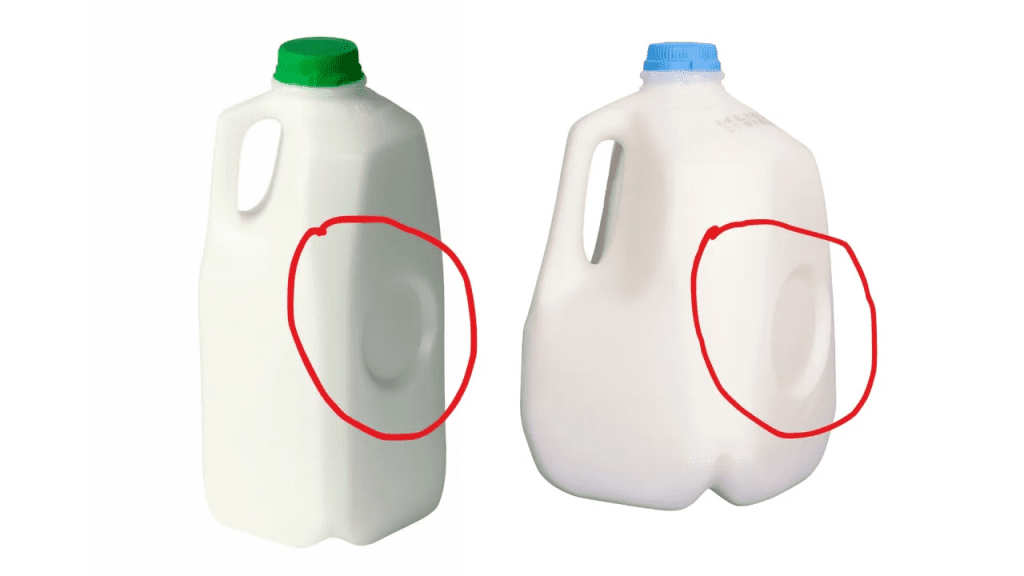

How the Dent Boosts Structural Integrity

Imagine trying to carry a water balloon without popping it. That’s what it’d be like transporting a full milk jug without the circular dent. Liquid puts pressure on container walls, especially when jugs are stacked in trucks or warehouse shelves. That dent acts like a shock absorber. It strengthens the jug without needing extra plastic.

When stacked with other jugs or jolted during delivery, the jug can flex slightly, keeping everything intact. That tiny dimple? It’s your milk’s unsung bodyguard.

Cutting Costs with Clever Engineering

You’d think making something stronger would mean using more plastic, right? Not here. The dent actually reduces the need for extra material. By reinforcing the structure using smart design instead of thicker plastic, manufacturers save money—and you pay less at the store.

And here’s the eco-friendly twist: using less plastic means fewer resources consumed and less waste. So, this little dent is doing its part for your wallet and the planet.

Preventing Spills and Messes at Home

Ever had a milk jug leak because it hit the floor? Accidents happen, but the dent helps prevent the worst-case scenario. It absorbs part of the impact when dropped, making it less likely that the jug will split or rupture. That’s a lifesaver in homes with small kids or chaotic mornings.

It’s the jug’s built-in defense system against milk disasters—and when you think about how messy a milk spill can be, that’s no small thing.

Video: Why Do Milk Jugs Have That Circle On The Side?

Aiding Recycling and Waste Reduction

Here’s something you probably didn’t expect: the dent actually makes milk jugs easier to recycle. Because of its structure, the jug is easier to crush, which helps save space during transportation to recycling facilities. More crushed jugs per truckload means fewer emissions and lower processing costs.

So that dent isn’t just protecting your milk; it’s also helping reduce plastic pollution. Small change, big impact.

A Subtle Tool for Branding and Shelf Appeal

Believe it or not, even the look of that dent has purpose. It gives milk jugs a bit of character, making them stand out just a little. Some companies even mold their logos or symbols into the dent area, turning a functional design into a branding opportunity.

It’s not just about utility—it’s also a way to catch your eye while you stroll down the dairy aisle. So next time you pick up your favorite brand, check that dent again—it might just have a signature touch.

Debunking the Myths: It’s Not a Mistake!

A lot of folks think the circular dent is a manufacturing error. Others assume it’s for grip or just an old leftover feature with no use today. None of that’s true.

This dent is deliberately engineered. It’s a multi-tasker—handling pressure, improving structure, reducing plastic use, preventing spills, helping with recycling, and even supporting branding. It’s a tiny marvel hidden in plain sight.

The Surprising Story of How Milk Jugs Got Smarter

Before plastic took over, milk came in heavy glass bottles. Sure, they looked classy, but they broke easily and were costly to produce. When plastic milk jugs entered the scene in the 1960s, it changed everything. Lighter, safer, and more affordable, plastic jugs quickly became the go-to option.

As the dairy industry evolved, so did the jug design. The circular dent emerged as part of an effort to make jugs more efficient and robust for mass distribution. That evolution continues today, with every little tweak—including the dent—helping manufacturers deliver milk safer, cheaper, and cleaner.

Conclusion: A Small Dent with a Big Role

It’s wild how something so simple can carry so much importance. That little circular dent on your milk jug isn’t just a bump—it’s a brilliant piece of engineering. It keeps your milk safe during shipping, protects against spills, cuts down on plastic waste, and even boosts recycling efficiency.

Next time you pour your morning cereal or add a splash of milk to your coffee, take a second to appreciate that small design feature. It might not seem like much, but it’s working hard behind the scenes to make your life easier, cleaner, and a bit more sustainable.