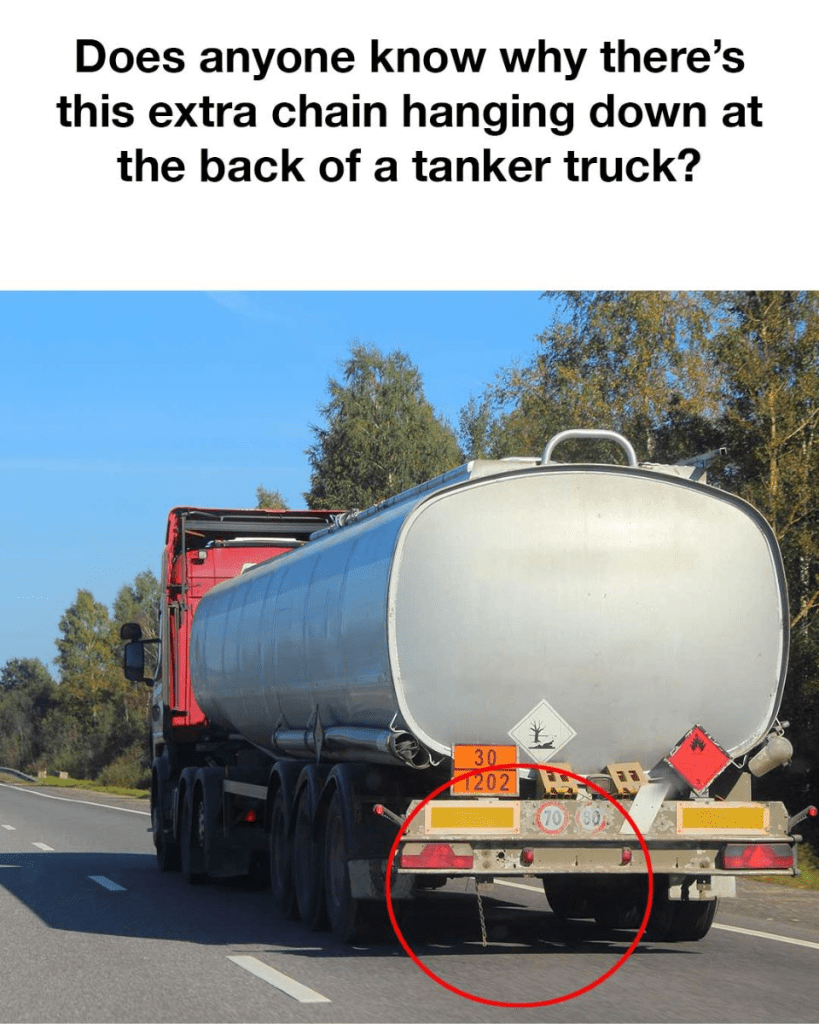

Tanker trucks are specialized vehicles designed for transporting liquids and gases, including fuel, chemicals, water, and food-grade substances. Their design ensures safe containment and efficient transport of these often volatile materials. One interesting feature you may have noticed is the extra chain hanging from the back of these trucks. At first glance, it might seem unnecessary, but this simple component plays a crucial role in safety.

So, what’s the real purpose of this extra chain? Let’s dive in and explore its importance in fuel transport safety.

The Purpose of the Extra Chain on Tanker Trucks

That dangling chain at the rear of a tanker truck isn’t just for show—it serves as a grounding device to dissipate static electricity. When transporting flammable liquids, such as gasoline or diesel, the movement of liquid inside the tanker can create friction. This friction builds up static electricity, which, if left unchecked, can lead to a dangerous spark.

A single spark near highly flammable vapors could result in a catastrophic fire or explosion. The extra chain drags along the ground, creating a path for static electricity to safely discharge into the earth, thereby eliminating the risk of ignition.

The History: Why Did Grounding Chains Become Standard?

The use of grounding chains became common after multiple fuel transport accidents occurred due to static discharge. In the early days of transporting petroleum, operators noticed an alarming pattern—some tanker fires were occurring without any visible external ignition sources.

Through extensive investigation, experts discovered that static buildup inside the tank was the culprit. Regulations and safety standards soon mandated grounding methods to eliminate this risk. The grounding chain became a widely adopted safety feature, significantly reducing incidents of fuel ignition caused by static electricity.

How Static Electricity Builds Up in Tanker Trucks

To understand why grounding chains are so critical, let’s take a closer look at how static electricity forms inside a tanker truck.

1. Movement of Liquid Creates Friction

As fuel or other liquids move around inside the tank, molecules rub against each other and the tank walls, creating an electrical charge.

2. Lack of Conductivity Increases Risk

Most tanker truck tanks are made of non-conductive materials or coated metal to prevent contamination. While this helps maintain fuel quality, it prevents static charge from naturally dissipating.

3. Discharge Can Cause Sparks

If the charge isn’t dispersed properly, it can suddenly discharge when the truck is near a conductive object, such as a fuel pump or another metal surface, potentially causing ignition of fuel vapors.

4. Grounding Chain Eliminates the Danger

By dragging on the ground, the grounding chain provides a direct electrical path for static to safely discharge, preventing the buildup of dangerous electrostatic energy.

Regulations and Safety Standards for Tanker Truck Grounding

Governments and regulatory bodies, such as the U.S. Department of Transportation (DOT) and the Occupational Safety and Health Administration (OSHA), enforce strict safety measures for hazardous material transport.

Some of these include:

✔️ Mandatory static electricity control measures

✔️ Regular inspections of grounding equipment

✔️ Proper use of grounding chains or static discharge systems

✔️ Safe loading and unloading procedures to prevent electrostatic discharge

Failing to comply with these regulations can result in heavy fines, increased accident risks, and liability issues for trucking companies.

Modern Alternatives to Grounding Chains

Although grounding chains are widely used, some modern fuel transporters incorporate additional static dissipation methods for added safety. These include:

1. Grounding Cables & Reels

Some tanker trucks are equipped with retractable grounding cables that drivers manually attach to a designated grounding point before fueling or unloading.

2. Static Dissipative Additives

Certain chemical additives are mixed into fuel to reduce static buildup, making it less likely to accumulate a dangerous charge.

3. Anti-Static Tank Linings

Newer tankers are being designed with specialized coatings that reduce static electricity generation within the tank.

Despite these advancements, the grounding chain remains a simple, cost-effective, and reliable safety measure, which is why many tanker trucks still use them today.

Common Misconceptions About the Extra Chain

There are several myths surrounding the purpose of the extra chain on tanker trucks. Let’s clear up a few of them:

🔸 “It’s just for decoration.” – False! It serves a vital safety function to prevent fuel-related accidents.

🔸 “The chain helps stabilize the truck.” – No, it does not provide any support or balance to the vehicle.

🔸 “It’s outdated technology and no longer needed.” – While modern alternatives exist, grounding chains remain a key component in tanker truck safety due to their simplicity and effectiveness.

The Role of Grounding Chains in Accident Prevention

The extra chain isn’t just an afterthought—it plays a crucial role in preventing deadly accidents. Here’s how:

✔️ Prevents Sparks Near Fuel Vapors – Eliminates the risk of an electrostatic spark igniting flammable substances.

✔️ Ensures Compliance with Safety Regulations – Helps fuel transporters meet strict safety standards.

✔️ Provides an Instant Grounding Path – Unlike other systems requiring manual connection, the chain works automatically as long as it drags on the ground.

✔️ Reduces Explosive Hazard Risks – By safely dissipating built-up charge, it protects drivers, cargo, and the public from potential disasters.

Regular Maintenance: Ensuring the Grounding Chain Works Properly

Like any safety feature, the grounding chain requires regular inspection and maintenance to stay effective. Tanker operators must check for:

🔹 Worn-out or broken links – A chain that’s damaged may not provide proper grounding.

🔹 Corrosion or rust – Rust can reduce conductivity, making the chain less effective.

🔹 Improper ground contact – The chain must maintain consistent contact with the ground to function correctly.

If a grounding chain isn’t working as intended, it should be replaced immediately to ensure continued safety.

Final Thoughts: Why This Simple Feature Is a Life-Saver

At first glance, the extra chain hanging from the back of a tanker truck might seem insignificant. However, it serves an essential function in preventing static-related fires and explosions. By grounding excess static electricity, it protects the vehicle, the driver, and everyone nearby.

Even with modern advancements in static control technology, grounding chains continue to be a crucial safety feature in fuel transportation.

So, next time you see a tanker truck on the road, take a closer look at that hanging chain—it’s a small but powerful tool keeping fuel transport safe!