When Machines Were Built to Last

If you’ve ever walked into an old gas station or vintage mechanic shop and seen a strange metal lever beside an air compressor, you were standing near a piece of engineering history — something that once made the ground tremble. It wasn’t decoration. It wasn’t for show. It was built for work, and for decades, it did that job better than anything else around.

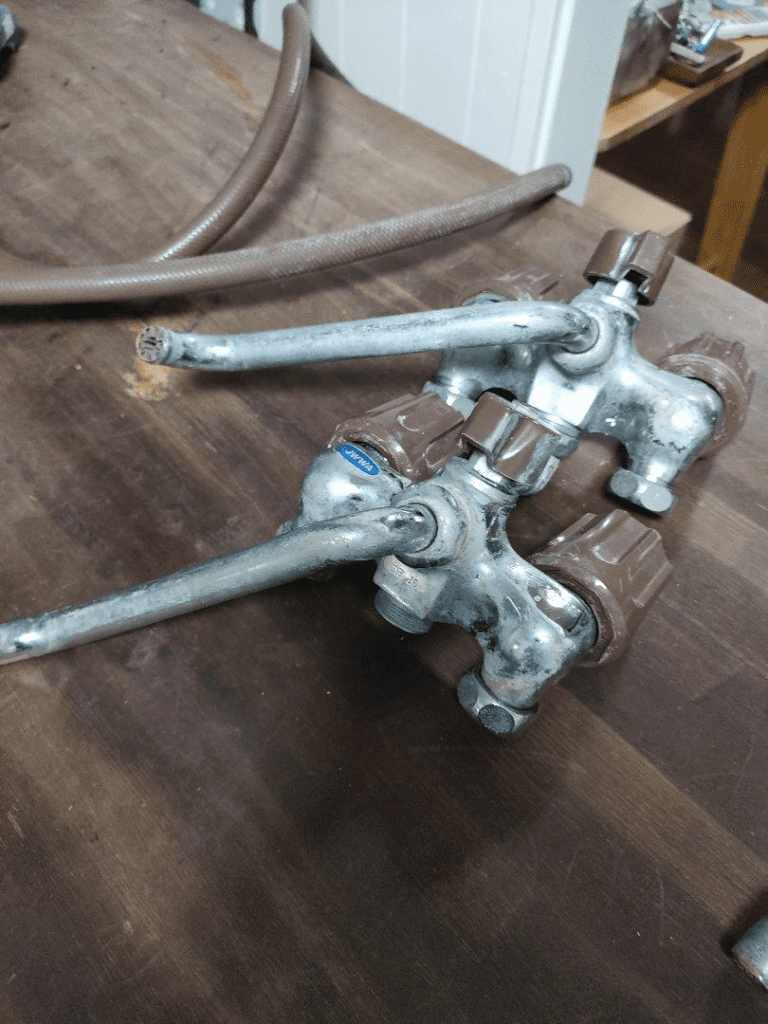

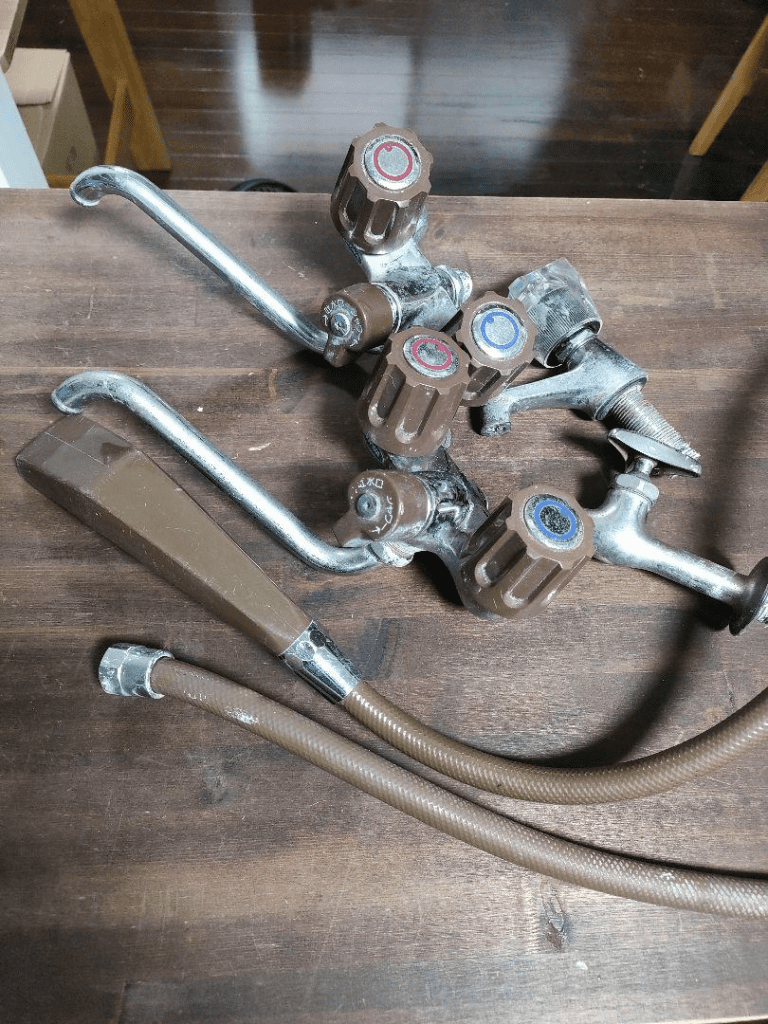

That device is known as a pneumatic lift control valve, or simply an air lifter control valve — the heart and soul of the air-powered lifting systems that defined mid-20th-century automotive service. In a time before computerized diagnostics and digital dashboards, this little lever gave mechanics the power to raise entire cars with nothing more than compressed air and a firm pull of the hand.

The Hidden Hero of Old Gas Stations

Back in the 1950s through the 1980s, garages and service stations relied on simple, rugged technology. Electricity was unreliable and even dangerous in places filled with gasoline fumes, oil vapors, and open flames. The solution? Air power.

Compressed air was clean, safe, and strong enough to move tons of steel with precision. Pneumatic systems could run tools, pumps, and — most importantly — vehicle lifts. These lifts used powerful air pistons hidden beneath the shop floor. And the control valve, usually mounted near the mechanic’s workstation, was the brain of the whole operation.

With a single lever, the operator could direct air into the lift cylinder to raise the car high above the floor. Pushing it the other way released the air, gently lowering the vehicle back down. No sparks. No wires. Just smooth, mechanical grace powered by pressure and ingenuity.

Video : Control Valve Spool Open.how To Work See

The Elegance of Simplicity

What makes these pneumatic lift control valves so fascinating today is their simplicity. Inside that small metal housing, there’s no circuit board or fancy sensor. Just a few precision-machined ports, a sliding spool, and rubber seals that direct compressed air in and out.

Yet this basic design delivered astonishing reliability. These valves could last decades without replacement. They didn’t overheat, short-circuit, or spark. Even when covered in grease and dust, they kept working — faithfully, quietly, and powerfully.

It was technology you could feel. Pull the lever, and the ground would rumble as air rushed into the lift. Push it back, and you’d hear a soft hiss as the pressure released, lowering two tons of steel with surgical precision. Mechanics didn’t just use these systems — they trusted them with their lives.

Why Pneumatics Ruled the Automotive World

In modern garages, you’ll mostly find electric and hydraulic lifts. They’re efficient, programmable, and connected to control panels that look more at home in an airplane cockpit than a mechanic’s bay. But in the golden age of service stations, pneumatics were king — and for good reason.

- Safety: Air systems eliminated the risk of electrical sparks in gasoline-rich environments. That made them the obvious choice for refueling stations and auto repair shops.

- Durability: With no moving pistons exposed to oil or rust, pneumatic lifts could handle decades of abuse.

- Simplicity: No power cords, no complicated wiring — just an air compressor, hoses, and a control valve.

- Ease of Maintenance: A mechanic could fix or replace seals and fittings in minutes, keeping the system running without costly downtime.

These systems were built not just to work — but to last. And many of them did. Some are still in use today in classic car restoration shops and vintage service stations around the world.

A Symbol of Mechanical Honesty

There’s something poetic about old pneumatic control systems. In an era before everything became digital and disposable, this little valve represented trustworthy engineering — the kind of design philosophy where every click, hiss, and motion had purpose.

To the mechanics who worked with them, these valves weren’t just tools — they were extensions of their hands. Pulling the lever was muscle memory, a rhythm learned through years of work. The sound of compressed air hissing through pipes meant one thing: another job getting done.

Video : Replacement Air Lift Table Valve Saves My Life! | Latest Sticker ShoutOut

Even today, those who’ve stood beside one can still remember the feeling — the floor shaking slightly as the lift rose, the mechanical growl of air pressure doing its work, and the pride of knowing that simple machines can still move mountains.

Why They’re Still Admired Today

Collectors, restorers, and mechanical enthusiasts still search for these vintage pneumatic valves, not just for function but for what they represent. They remind us of an era when craftsmanship mattered, when equipment was built heavy, and when power came from physics, not processors.

In a world of digital everything, the air lifter control valve remains a testament to analog brilliance — a small piece of metal that carried an entire industry on its shoulders. Its beauty lies not in complexity, but in the raw honesty of its design.

Many enthusiasts proudly display these old control valves as conversation pieces — relics of a time when gas stations were full-service, mechanics wore pressed uniforms, and a handshake meant something.

Conclusion

The next time you come across one of these sturdy old pneumatic valves, take a moment to appreciate it. That lever once lifted cars, carried trust, and kept mechanics safe in an era that relied on skill more than sensors.

It’s not just a control valve. It’s a story — of craftsmanship, innovation, and a time when machines had soul.

Because sometimes, the most powerful things in the world don’t make noise to be noticed. They simply work, decade after decade, with the quiet confidence of something built to last.