A Secret Weapon in Skilled Hands

Once upon a time, in the heart of every woodworking shop, nestled between the chisels and mallets, sat a curious tool that held a quiet kind of power. Small, heavy, and sleek—this was the shoulder plane, also known as the rebate plane. It wasn’t flashy, and it didn’t roar like a power tool, but in the hands of a master craftsman, it could do something magical: shape the perfect joint, smooth a tenon’s shoulder, and whisper precision into every corner of a piece.

But let’s be honest—when was the last time you even saw one?

What Exactly Is a Shoulder Plane?

If you’re new to woodworking or just never got your hands dirty in traditional joinery, you might be scratching your head. So let’s break it down.

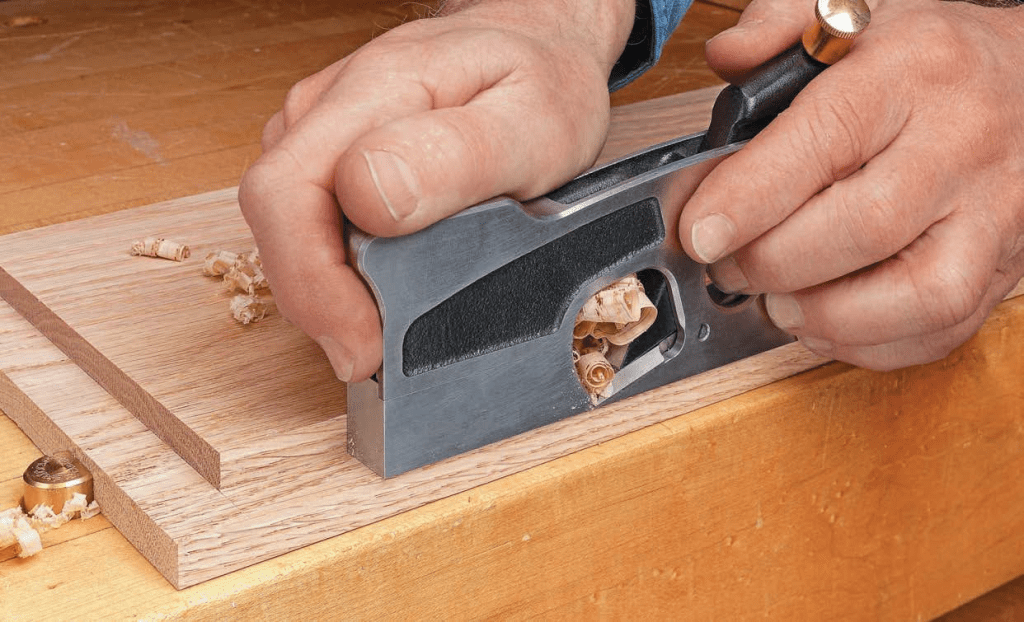

A shoulder plane is a specialized hand tool used primarily to trim the shoulders and cheeks of tenons—a critical task in fine joinery. Unlike a regular bench plane, its blade spans the full width of the body, allowing it to cut all the way into corners. That makes it a go-to for fitting joints with absolute precision.

It’s like the scalpel of the woodworking world—delicate, deliberate, and deadly accurate.

Video: These Tools all do the SAME THING?? #woodworkingtips #woodworking #diy

How It Was Once the Gold Standard in Joinery

Back when furniture was built to last generations, not just until the next move, shoulder planes were indispensable. Skilled craftsmen relied on them to create joints so flush and clean you could barely see the seam.

There was no “good enough.” Everything had to fit like a glove.

Whether it was cabinet making, crafting doors and window frames, or laying out mortise and tenon joints for heirloom furniture, the shoulder plane did the job no other tool could quite match. It was the difference between “handmade” and “hand-crafted.”

Why Shoulder Planes Have Faded From Popular Use

Let’s not sugarcoat it—technology changed the game. Power tools and CNC machines took over the precision tasks. With routers, jointers, and table saws doing most of the heavy lifting, hand planes of all kinds took a back seat.

And let’s face it: mastering a shoulder plane takes time. There’s a learning curve. You need the right grip, a feel for the grain, a sharp blade, and a steady hand. Most modern DIYers don’t have the patience—or the time—to develop that kind of finesse.

Add to that the fact that fewer people are learning traditional woodworking, and it’s no surprise these elegant tools are collecting dust in vintage tool shops and basements.

What Made the Shoulder Plane So Special?

You might wonder, “What’s the big deal? Can’t I just sand down a joint or use a router?” Sure, you can. But here’s the thing:

A shoulder plane doesn’t just remove wood—it finesses it.

It gives you control at a level that machines can’t. Want to shave off just a hair to fit a stubborn tenon? Done. Need to fine-tune a rabbet edge without touching the surrounding surface? No problem.

Plus, there’s something undeniably satisfying about using it. The whisper of the blade against the grain. The silky smooth finish. The sense of control and pride. It’s like comparing a handwritten letter to a text message—one just feels more human.

Video: Lie-Nielsen vs. Veritas Shoulder Planes | Tool Duel #6

Still Useful Today? You Bet. Here’s Why.

Sure, we live in the age of power tools and precision lasers, but the shoulder plane still has its place—especially among passionate woodworkers and restoration experts.

In fact, for those who do fine joinery, furniture making, or antique repair, shoulder planes remain invaluable. They allow for last-minute adjustments, tight fits, and clean lines that no orbital sander or router bit can deliver with the same level of tactile feedback.

And they’re quiet. No dust collection. No ear protection. Just you, the wood, and a connection to a centuries-old tradition of craftsmanship.

How to Bring This “Secret Weapon” Back Into Your Workshop

Thinking of giving the shoulder plane a second chance? Here’s how to make it work for you:

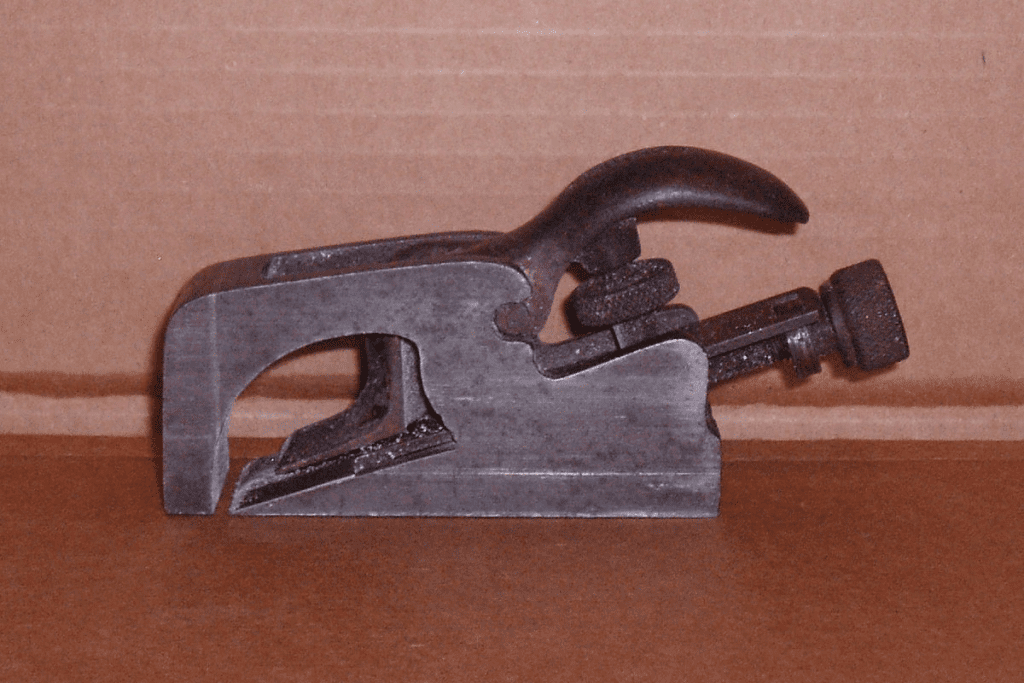

- Choose the Right One: Look for a shoulder plane with a flat sole, a sharp blade that spans the full width, and a solid grip. Brands like Veritas, Lie-Nielsen, or even vintage Stanley models are great places to start.

- Keep It Sharp: The key to success is razor-sharp edges. Invest in a sharpening stone and learn the basics of honing your blade.

- Practice on Scrap: Before using it on your project, practice trimming tenon shoulders on scrap wood. Feel the grain, learn how the tool responds.

- Use It for Final Fits: Don’t think of the shoulder plane as a roughing tool. Think of it as your precision finisher—the last word in making a joint perfect.

Conclusion: A Quiet Legend Worth Remembering

The shoulder plane isn’t obsolete—it’s just waiting for someone who understands its value. In a world of speed and convenience, it reminds us of something deeper: that craftsmanship takes time, patience, and the right tools.

So if you find one buried in your granddad’s old toolbox or spot one at a flea market, don’t pass it up. That little block of steel and wood was once a craftsman’s secret weapon—and it could be yours, too.

After all, in woodworking—as in life—it’s the little details that make the biggest difference.